SERVICES

Development and management of timber frame projects: from the original idea to the assembly of the

original idea to the assembly of the structure on site.

Technical consultancy

We offer technical advice from the earliest stages of the project, to define the best structural solutions in wood. Our team brings solid experience in the application of regulations and in-depth knowledge of material behaviour and construction feasibility, helping to identify risks and opportunities from the outset.

Feasibility studies

We carry out preliminary analyses by means of structural pre-dimensioning, which facilitate the development of the project from the earliest stages. These studies allow us to evaluate different construction alternatives, materials and structural systems, providing a solid technical basis for decision-making. Our comprehensive approach helps to optimise resources, costs and time, guaranteeing the technical and economic viability of each proposed solution.

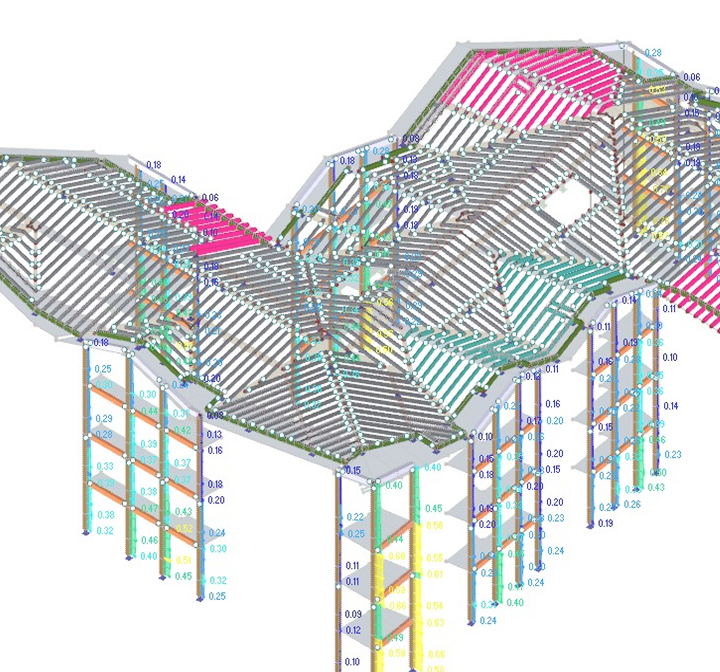

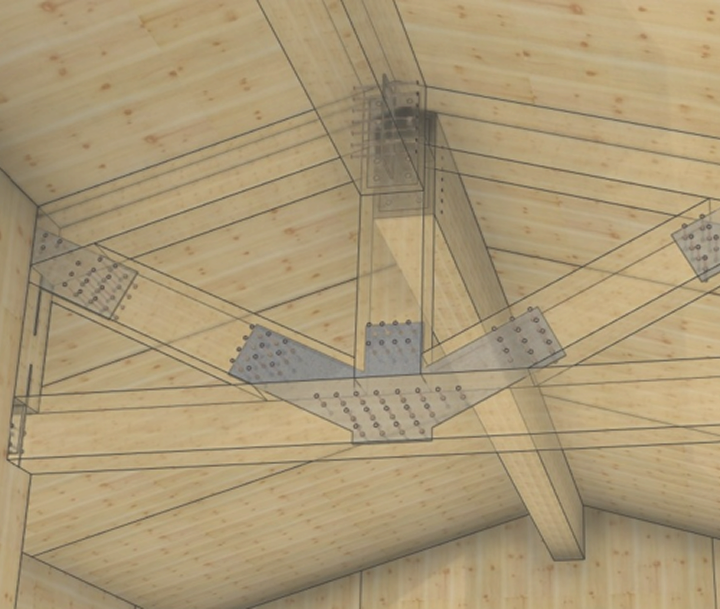

Calculation and design of timber structures

We develop advanced calculations and accurate structural designs using 3D modelling with finite element software (RFEM). This allows us to analyse in detail the global behaviour of the structure and the specific stresses in each element. In addition, we perform detailed calculations of joints, fittings and connections, ensuring the strength, stability and durability of each critical point. Our experience covers CLT, glulam and light-frame structures, guaranteeing safety, efficiency and regulatory compliance at all levels of the project.

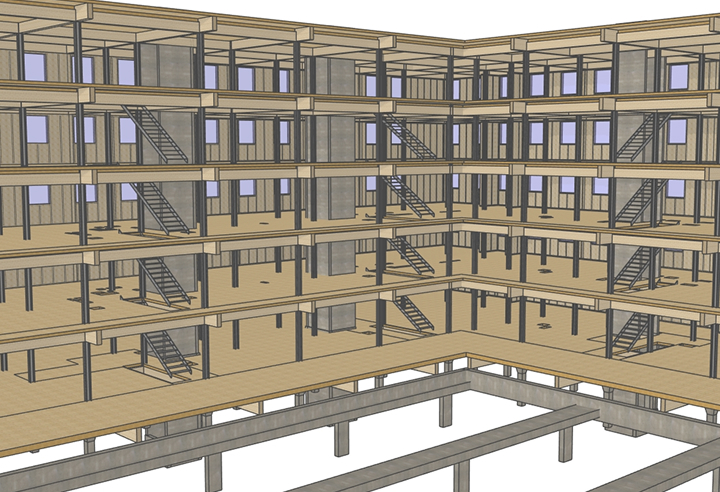

BIM design

We integrate multidisciplinary BIM models using specialised wood software such as Cadwork, which allows us to reconcile information from different platforms and reach an optimal level of detail for industrialised manufacturing. Thanks to these tools, we can generate accurate models for CNC machining, guaranteeing accuracy and efficiency in the production and assembly of each element. In addition, we incorporate the management of site documentation such as topographic surveys or point clouds, facilitating the adaptation of the model to the real conditions of execution and improving coordination between all the agents involved in the project.

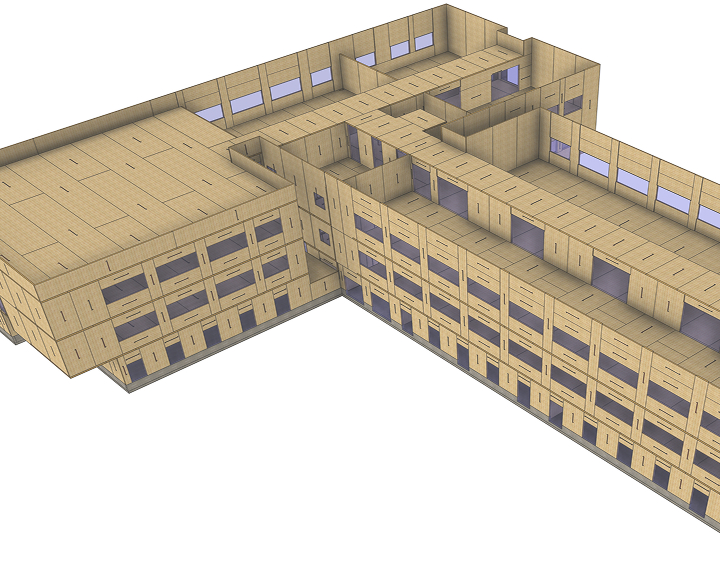

Industrialized manufacture of wooden elements

We prepare all the necessary documentation for the industrialised manufacture of each wooden element: exploded views of CLT panels, detailed configuration of beams, light-framed walls, joints, fittings, etc. We ensure the traceability and precision of each component so that production and assembly meet the most demanding expectations.

Structure assembly

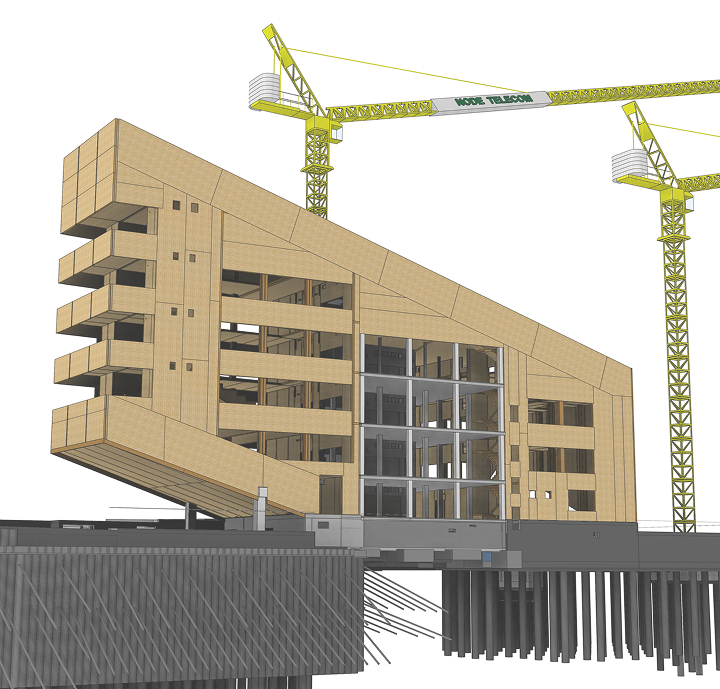

We generate clear, precise and easy-to-understand plans that simplify on-site assembly, adapting the technical information so that it is accessible to everyone, even in the most complex projects. In addition, we produce interactive 3D models that can be viewed from any device without the need for specialised software, allowing quick and easy verifications directly on site. These resources detail the assembly sequence, connections and coordination with other trades, ensuring a smooth and efficient process that minimises errors and delays.

Project management

We provide support at all stages of the development of timber frame projects, from the conception of the model to the construction site, including logistics, stockpiling and the planning of lifting and assembly equipment to ensure that time and resources are optimised. Our monitoring during execution ensures correct commissioning, resolving any incidents and guaranteeing the final success of the project.